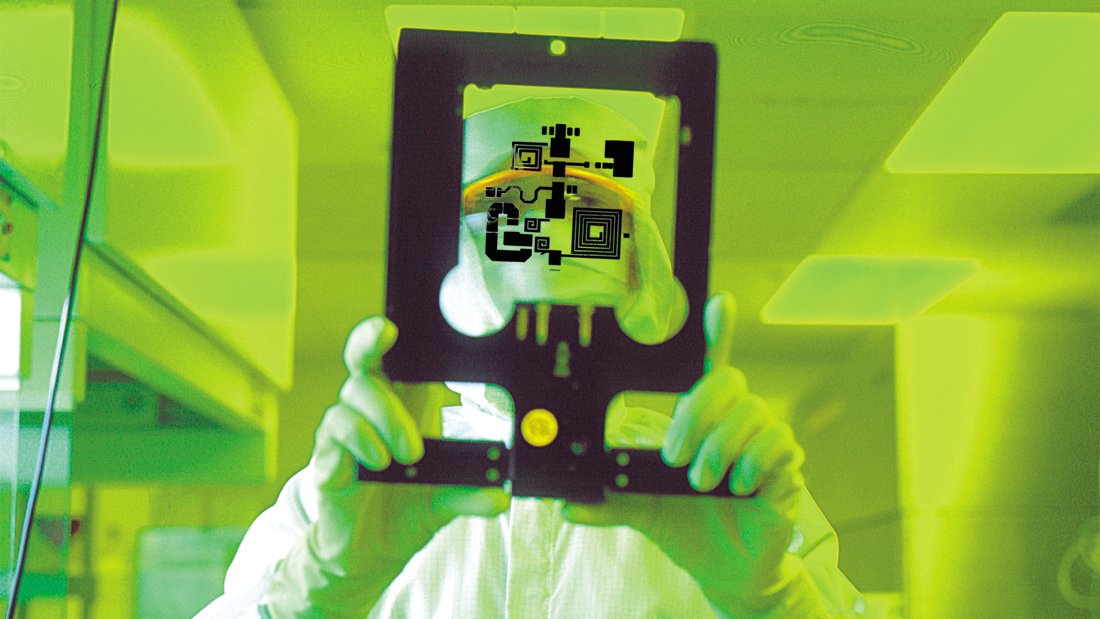

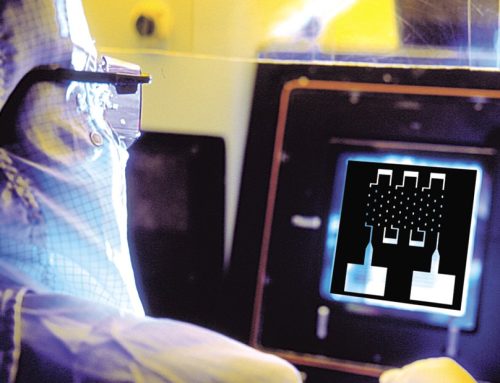

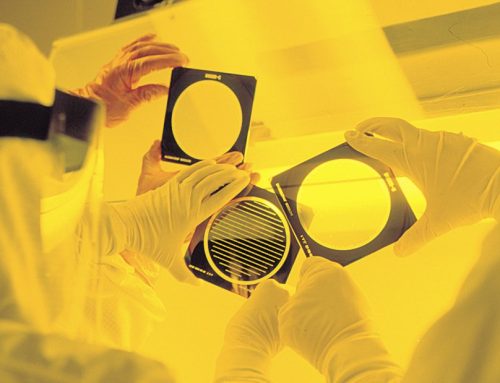

Mask writing is the process of writing the pattern design (geometry) onto the photomask.

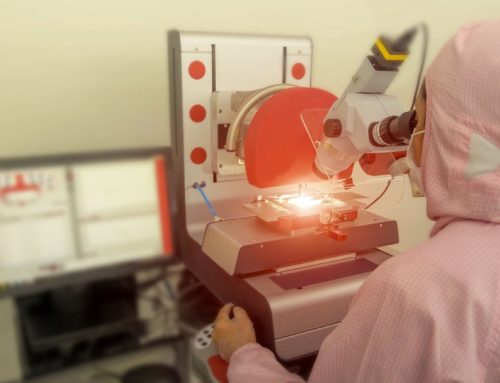

The writing equipment writes the geometry onto the blank mask plate by exposing the photo resist to a UV light source, a laser or an electron beam. This exposure changes the molecular composition of the photo resist. During the developing process, resist that has been exposed is either removed, or hardened depending on the photo resist type (positive or negative). With a positive photo resist, the exposed area is washed away (removed) during the development process. With a negative photo resist, the exposed area is hardened during the exposure causing the hardened area to remain while the unexposed regions wash away.

Maskmakers typically use a positive photo resist process for optical exposures (UV & Laser), and a negative process for electron beam exposures. While all the different types of exposure sources can expose either positive or negative photo resist, you will find that most maskmakers will only offer one or the other for each exposure system (write tool).

The designer / end-user of the photomask should not be greatly concerned with which photo resist process a given maskmaker uses. The designer’s / end-user’s concern should be focused on clearly communicating the desired tone for the digitized and non- digitized areas of the photomask. The maskmaker can achieve any desired tone by changing a setting on the write tool, or adding an instruction to the fractured data, which will instruct the exposure system to expose either data or background.

Using the correct dose of energy is critical to achieve properly defined features. Over exposure can result in feature sizes that are over-sized, have rounded corners or are otherwise misshapen. Under exposure can result in under-sized features, or in extreme instances, unresolved features or partially resolved features.