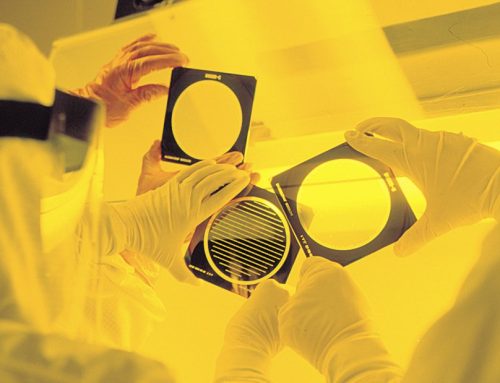

SUBSTRATE TYPE

There are two most common types of substrate material used for making photomasks are quartz (fused silica) and Soda Lime. The advantages of quartz are its good transparency even for Deep Ultra Violet (DUV) wavelengths at 246 nm or 193nm and its very low thermal expansion coefficient. The low expansion coefficient becomes very important for large die sizes and accurate alignment of multiple mask layers onto a substrate.

Because of the differences in coefficient of expansion between quartz and soda lime, the two substrate materials should not be intermingled within a set of photomasks. Even when used in identical environments there will be a substantial difference in overall pattern size from one substrate type to the other. That difference can be as great as 2.8 across a 4.0” area.

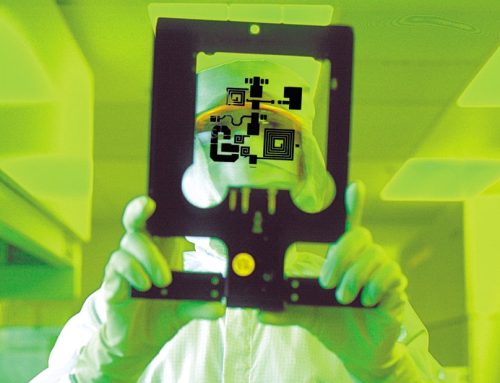

METALIZATION COATING

The substrate (quartz or soda lime) is coated on one side with a material that is opaque to UV wavelengths. The opaque material is deposited on the substrate using a thin film deposition method, usually sputtering. This opaque material can be either a very thin layer of chrome (=900 A°) covered with an anti-reflective coating of chrome oxide (^200A°), or simply a thin layer of FeO2 (Iron Oxide) (=2200 A°).

In order for FeO2 to be opaque to UV light, it must be twice as thick as chromium/chrome oxide coatings. This thicker coating results in undercutting during longer etch times and yields poorer quality feature edges. A properly exposed and processed chrome oxide photomask will always have features with sharper edges than those that can be achieved on iron oxide.

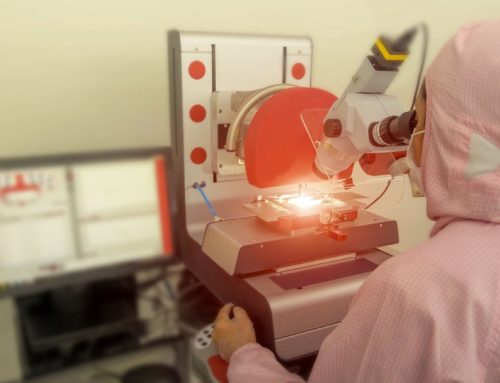

PHOTO RESIST COATING

A photosensitive chemical called photo resist is spin-coated over the AR-Chrome or the FeO2 to a thickness of approximately 5300A0. This photo resist can be either positive or negative. A positive photo resist responds to UV light in such a way as to make the exposed regions soluble. The exposed regions will be washed away during the developing step that follows the exposure. A negative photo resist acts in the opposite way, wherein the exposed regions are hardened and remain in place after development. In either case, the remaining photo resist becomes a barrier during the etching process.

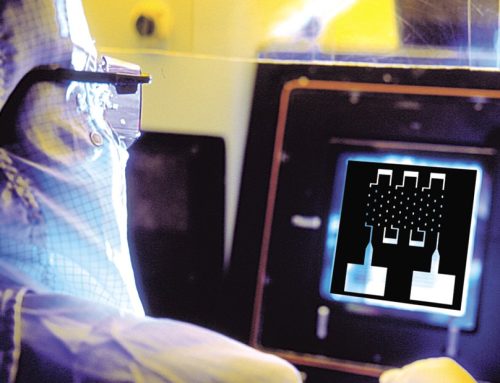

PHOTOMASK BLANK

A quartz or soda lime glass substrate that has been coated with an opaque, thin film metal coating followed by a photo resist coating is called a blank. The blank is the mask maker’s raw material. After exposure, develop and etch, the photomask blank becomes a photomask.