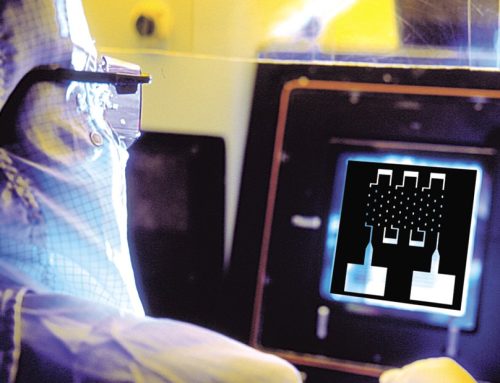

The photo resist development is a critical step in photo resist processing because it plays a key role in defining the shape of the features and controlling the line width or critical dimension (CD).

Most positive photo resists use alkaline developers.

While it is possible to develop an image by dipping the exposed mask in a bath of developer solution while agitating it, most mask makers use spin-and-spray systems. The spin-and-spray method is superior to bath development. In this process the exposed photomask is secured in a chuck, with the exposed side facing up. A fine mist of developer solution is sprayed on the exposed surface as the photomask spins in its chuck. The result is a uniform development, yielding consistent results across the entire surface of the photomask. Fresh developer solution is used for each photomask, yielding more consistent results from photomask to photomask. The bath development is less controllable, because the developer solution is depleted somewhat after each use, resulting in longer develop times for subsequent photomasks.

Using the correct amount of time to insure thorough development is critical to achieve properly defined features. Over development can result in feature sizes that are over- sized, have rounded corners or are otherwise misshapen. Under development can result in under-sized features, or in extreme instances, unresolved features or partially resolved features.

Using a positive photo resist, only the regions exposed by the write tool will be removed. Using a negative photo resist, only the unexposed regions will be removed.

Following development, the masks are rinsed in de-ionized water to remove the remaining developer.

Resist development.

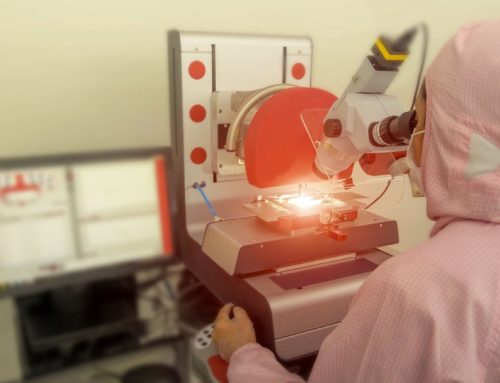

ETCHING:

Etching removes the metallic coating in the regions where the photo resist has been removed in the development process.

The selective etching of the metal uncovered during the development process is a critical step in the photomask manufacturing process. Etching plays a key role in defining the shape of the features and controlling the line width or critical dimension (CD).

While it is possible to etch a developed photomask by dipping the mask in a bath of etchant solution while agitating it, most mask-makers use spin-and-spray systems. The spin-and-spray method is superior to bath etching. In this process the photomask is secured in a chuck, with the chrome side facing up. A fine mist of etchant solution is sprayed on the chrome surface as the photomask spins in its chuck. The result is a uniform etching, yielding consistent results across the entire surface of the photomask. Each photomask blank is sprayed with fresh etchant solution, yielding more consistent results from photomask to photomask. Bath etching is less controllable, because the etchant solution is depleted somewhat after each use, resulting in longer etch times for subsequent photomasks.

Using the correct amount of time to insure complete etching is critical to achieve properly defined features. Over etching can result in feature sizes that are over-sized, have rounded corners, ragged edges or are otherwise misshapen. Under etching can result in under-sized features, or in extreme instances, unresolved features or partially resolved features.

Following the etching step, the masks are rinsed in de-ionized water to remove the remaining etchant solution.

After exposure and development.

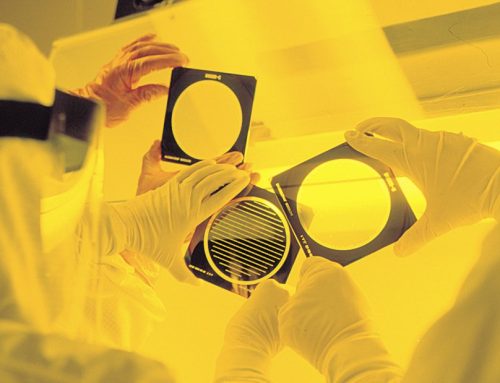

STRIPPING & CLEANING:

After development and etching, the remaining photo resist, which until this time has acted as a barrier to the etchant, must be removed. The photomask is soaked in a stripping solution for an appropriate amount of time to insure that all of the remaining photo resist has been removed.

After stripping, the photomask is cleaned & dried using specialized equipment.

After strip.

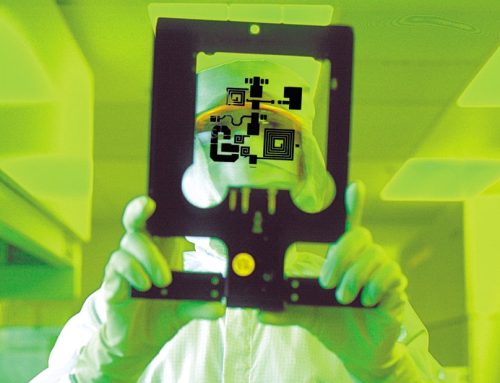

Areas where the coating has been removed are referred to as clear. Areas where the

coating remains are referred to as dark or opaque.