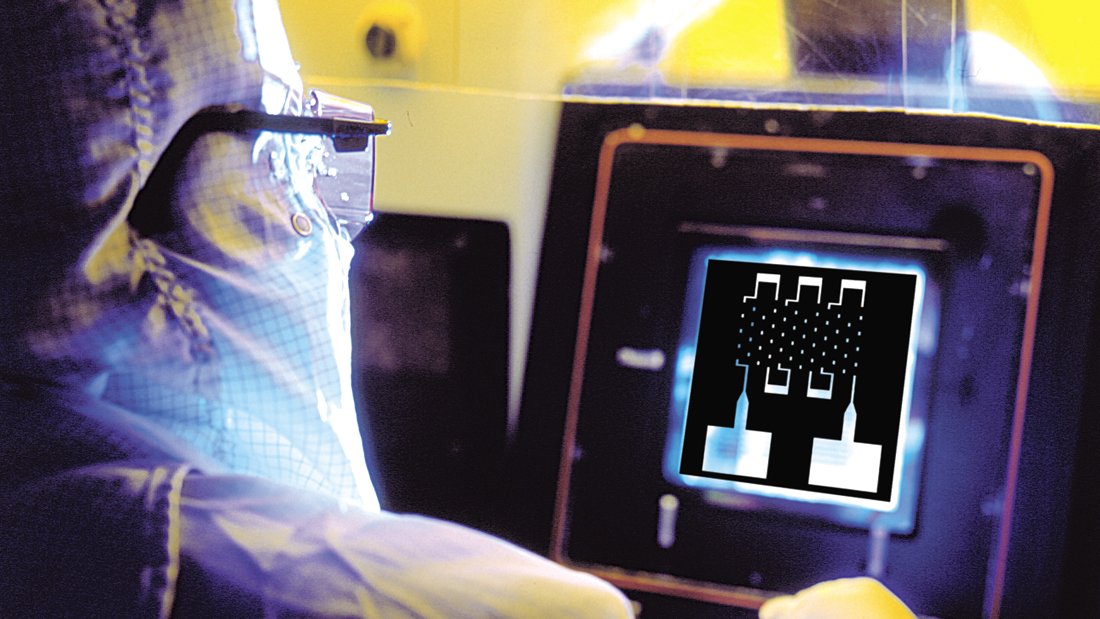

Simply put, a photomask is an image-transferring tool.

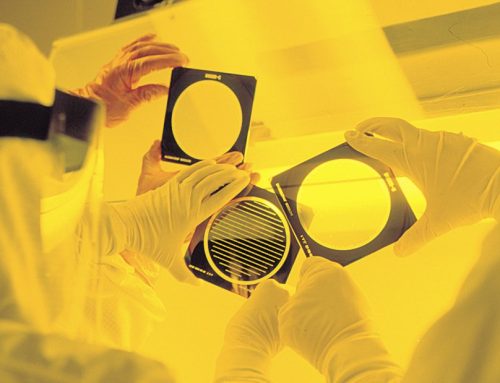

Photomasks are comprised of a solid, transparent substrate, such as glass or fused silica, showing an opaque coating on one of the surfaces where a microscopic pattern has been etched, leaving some regions transparent and others opaque. The opaque regions does not allow mask light to pass through, while the transparent regions does allow light to pass through.

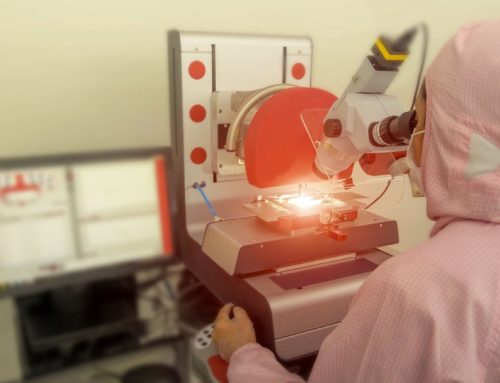

The photomask is placed adjacent to another substrate, like a silicon wafer that is coated with a photosensitive material, called photo resist. Light travels through a photomask, exposing certain regions of photo resist on the adjoining substrate, while the opaque regions protect the photo resist from being exposed.

Micro-lithography is one of the principle technologies for miniaturizing circuitry, which in turn has led to the computerization of everything from cars to microwave ovens to exercise equipment and countless other devices. Each small technological advance in photomask technology has led to even larger technology advances in semiconductor processing.

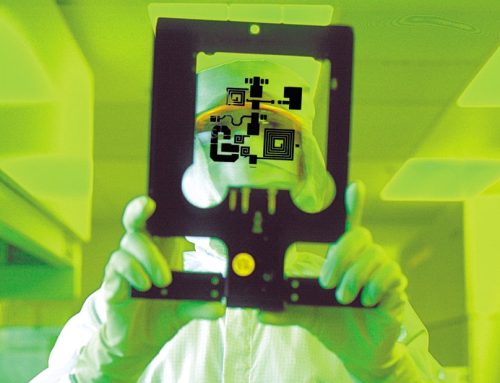

The semiconductor industry is not the only industry to utilize and benefit from photomask technology.

Photomasks are used extensively to produce devices for consumer products, computers and peripherals, military products, automotive products and medical and biomedical products. Countless universities throughout the world use photomasks for research and development as well as developing new technologies.

Microlithography is one of the principle technologies for miniaturizing circuitry, which in turn has led to the computerization of everything from cars to microwave ovens to exercise equipment and countless other devices we take for granted in our everyday lives. Each small technological advance in photomask technology has led to even larger technology advances in semiconductor processing.

The semiconductor industry is not the only industry to utilize and benefit from photomask technology. Photomasks are extensively used in the manufacturing of optical devices, electro-optical devices, hybrid circuitry, resistor networks, liquid crystal displays (LCD’S) and Micro Electromechanical Systems (MEMS). Photomasks are used extensively to produce devices for consumer products, computers and peripherals, military products, automotive products and medical and biomedical products. Countless universities throughout the world use photomasks for research & development as well as developing new technologies.